全国免费咨询热线:17317317121(微信同号)

橡胶气囊在施工前的介绍

来源:上海松夏减震器有限公司 发布时间:2019-05-06 16:27

抗渗性是橡胶气囊的重要功能之一。橡胶在一定压力下阻塞空气通道的能力。气压越高,防气性能越好。

Impermeability is one of the important functions of rubber air bag.The ability of rubber to block air passages at a given pressure.The higher the air pressure, the better the anti-air performance.

所有能够成膜的橡胶安全气囊都不具有储气功能,因为一些聚合物含有亲水性基团。

All membrane-forming rubber airbags do not store energy because some polymers contain hydrophilic groups.

有些聚合物分子中含有亲水性基团,这些亲水性基团对水分子的亲和力大于水分子之间的氢键力,从而破坏了水分类聚合物材料的储气功能,例如聚醋酸乙烯乳液的涂膜在水之后是一种白色现象,即水分子穿透聚合物的内部。

Some polymer molecules contain hydrophilic groups, and the affinity of these hydrophilic groups to water molecules is greater than the hydrogen bond force between water molecules, thus damaging the storage capacity of water-classified polymer materials. For example, the coating film of polyvinyl acetate emulsion is a white phenomenon after water, that is, water molecules penetrate the interior of the polymer.

合并时间是从橡胶被激活到失效的时间。在使用双组分橡胶之前,需要将两种组分充分混合并搅拌至平均,并且两种组分经历必要的化学反应,最终成为交联的三维结构橡胶。合并时间是指从组分的化学反应开始到失去构造功能的时间。超过这个时间,橡胶的构造已经成为一个问题,并且橡胶的各种功能指标不能得到有效保证。

The merge time is the time from rubber activation to failure.Before the use of two-component rubber, the two components need to be fully mixed and stirred to the average, and the two components go through the necessary chemical reaction, and finally become a cross-linked three-dimensional structure of rubber.The combination time refers to the time from the chemical reaction of components to the loss of structural function.Beyond this time, the construction of rubber has become a problem, and rubber's various functional indicators can not be effectively guaranteed.

施工前应均匀搅拌胶球,特别是双组分反应胶球。涂层施工完成后,会逐渐交叉连接形成薄膜。有些溶剂或气体不能完全排出,在使用过程中会逐渐蒸发,造成橡胶体积和尺寸的变化。橡胶会产生很强的内应力。在长期的内应力作用下,会产生材料。加速老化、开裂,甚至失去防气功能。热膨胀率是一项技术性能指标,用来确定橡胶在受热后的形状变化。

Before construction, the rubber ball should be mixed evenly, especially the two-component reaction rubber ball.After the coating is finished, it will gradually cross connect to form a film.Some solvents or gases can not be completely discharged, in the use of the process will gradually evaporate, resulting in rubber volume and size changes.Rubber produces a strong internal stress.Materials are produced under long-term internal stress.Accelerate ageing, craze, lose prevent qigong energy even.Thermal expansion rate is a technical performance index used to determine the shape change of rubber after heating.

转向架工业空气弹簧企业互联网时代的到来,很多企业走电商之路,不少空气弹簧企业也坐不住了,纷纷开始“触电”。然而,部分品牌“触电”逐渐演变成形式主义。空气弹簧企业需…

确定合理的橡胶空气弹簧参数 (1)橡胶空气弹簧工作原理 橡胶空气弹簧是一个内部充以一定压力氮气或空气的密闭容器,其基本功能是利用气体的可压缩性,随着吸入压力和排出压…

福建橡胶充气囊宝马多少钱柴油发电机组的主要噪声源均为柴油机产生,包括排气噪声、机械噪声和燃烧噪声、冷却风扇和排风噪声、进风噪声、发电机噪声、地基振动的传递所产生的…

空气弹簧百度文库1、液压传动是以液体作为橡胶橡胶空气弹簧介质来进行能量传递的一种传动形式,通过能量转换装置,将原动机的橡胶橡胶空气弹簧能转变为液体的压力能,然后通过…

天津橡胶密封气囊充气方法动平衡检测机发展迄今已经有一百多年的历史。直到上世纪末40年代,所有的平衡工序都是在采用纯机械的平衡设备上进行的。转子的平衡转速通常取振动系统…

甘肃橡胶水堵气囊是什么材质3、能够有效隔离各类卧式、立式水泵、风机、空调机组、发电机组、管道、等动力设备的振动,并保护及延长其使用寿命上海松夏减震器有限公司致力于风…

与橡胶气囊在施工前的介绍相关的产品

-

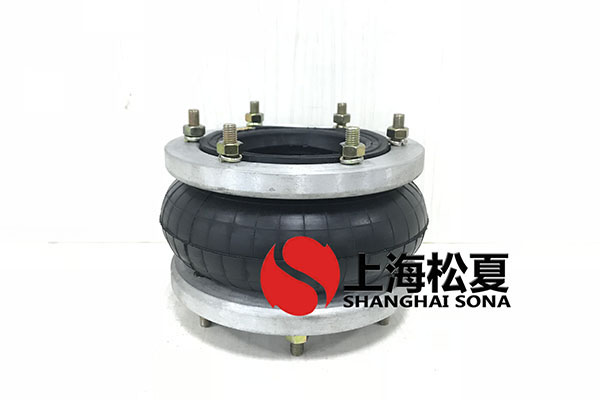

HF215/120-1法兰式橡胶空气弹簧,纠偏气囊

HF215/120-1法兰式橡胶空气弹簧,纠偏气囊 橡胶空气弹簧 产品介绍: 橡胶空气弹簧是一种由橡胶、网线贴合成的曲形胶囊,俗称橡胶气囊、橡胶空气弹簧、橡胶皮囊、橡胶气胎、波纹气..

-

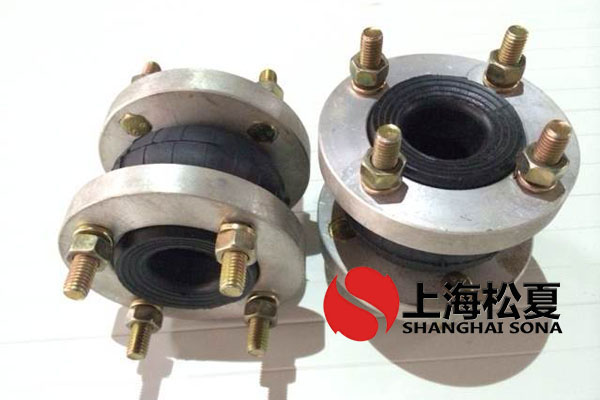

S-300-2R台式冲床气囊ZF-300-2高速冲床空气弹

ZF型自封式橡胶气囊(冲床设备专用)介绍: 自封式,是因其无需外力自行密封而得名。如图,用纤维层做补强处理的橡胶曲囊①在使用时,将防止膨胀的钢制(镀锌)腰环②嵌在其中。③盖..

-

S-220-2RLED支架冲床空气弹簧S-220-2R电动冲床

ZF型自封式橡胶气囊(冲床设备专用)介绍: 自封式,是因其无需外力自行密封而得名。如图,用纤维层做补强处理的橡胶曲囊①在使用时,将防止膨胀的钢制(镀锌)腰环②嵌在其中。③盖..

-

HF150/076-2橡胶气囊 调偏专用纠偏气囊

HF150/076-2橡胶气囊 调偏专用纠偏气囊 橡胶气囊产品介绍: 橡胶空气弹簧是一种由橡胶、网线贴合成的曲形胶囊,俗称橡胶气囊、橡胶空气弹簧、橡胶皮囊、橡胶气胎、波纹气胎、皮老..

与橡胶气囊在施工前的介绍相关的文章

- 通用双台体振动使用橡胶减震气囊 2024-05-14

- 矿山设备使用橡胶空气减震器 2024-05-14

- 皮革震荡机械使用橡胶空气弹簧 2024-05-14

- 小型振动试验系统使用箍环密封式气囊 2024-05-14

- 废水回收处理系统不锈钢金属软管 2023-08-30

- 高频红外碳硫分析仪气浮式隔振器优势和应用有哪些? 2023-08-22

- 手动影像测量仪气浮式隔振器有哪些优势? 2023-08-22

- 全自动芯片排片机空气弹簧隔振器的优势有哪些? 2023-08-10

- 俄歇电子能谱仪空气隔振器的应用有哪些? 2023-08-10

- 热裂解进样系统为何需要空气隔振器? 2023-07-31

全国免费咨询热线:17317317121

上海松夏减震器有限公司 沪ICP备09066468号-13 网站地图 站点地图